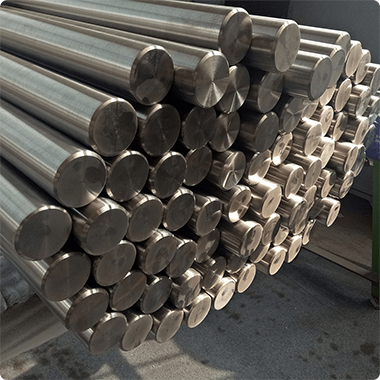

Titanium Hollow Bar

What is Titanium Bar?

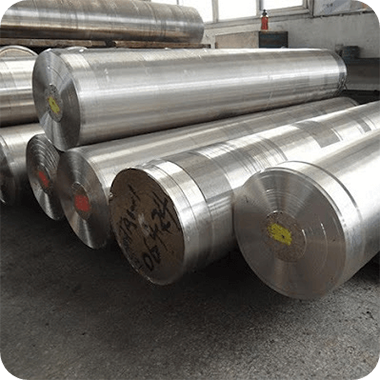

A titanium bar is a solid piece of titanium metal that has been shaped into a cylindrical form. It is a highly durable and corrosion-resistant material that is widely used in aerospace, medical, and industrial applications. Titanium bars are commonly used as raw material for machined parts, fasteners, and prosthetic implants. They are also used in the construction of aircraft frames, engines, and landing gear due to their high strength-to-weight ratio and resistance to fatigue. Titanium bars can vary in size and grade depending on their intended use.

Advantages of Titanium Bar

Ⅰ. Strength and durability

Titanium is known for its high strength and durability. It has a high strength-to-weight ratio, which means that it can withstand a lot of force without becoming deformed or breaking.

Ⅱ. Corrosion resistance

Titanium bar is highly resistant to corrosion, making it ideal for use in environments where other metals would easily corrode. It can withstand exposure to saltwater, chemicals, and other corrosive substances, making it a popular choice in marine and chemical industries.

Ⅲ. Biocompatibility

Titanium bar is biocompatible, which means that it can be used in medical implants and devices without causing any adverse reactions or toxicity in the body. It is also commonly used in the production of orthopedic implants and dental implants.

Ⅳ. Heat resistance

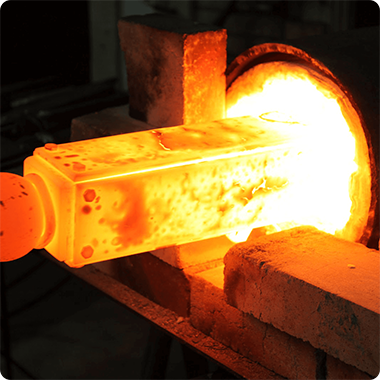

Titanium bar has a high melting point and can withstand high temperatures without losing its strength or becoming deformed. This makes it ideal for use in high-temperature applications such as aerospace or industrial manufacturing.

Ⅴ. Lightweight

Despite its strength and durability, titanium bar is a lightweight material, making it ideal for use in applications where weight is a concern. It is commonly used in aerospace and automotive industries because of its lightweight properties.

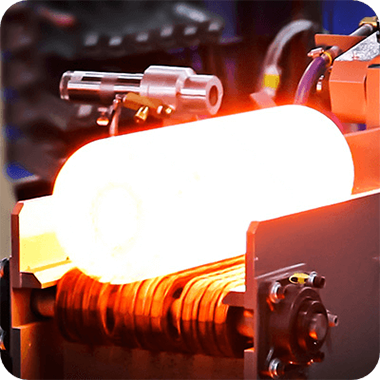

1_Titanium-Sponge 2_Compacting-Electrodes 3_VAR-Melting

4_Finished-Ignots 5_Forging 6_Bar-Billets

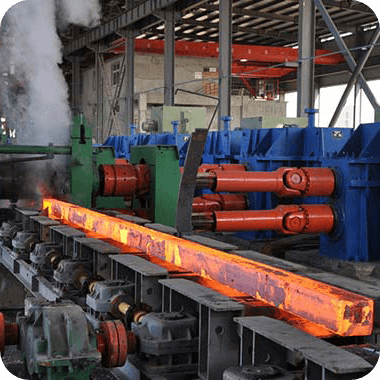

7_Cutting-Billets 8_Extruding 9_Rolling

10_Straighting 11_Machining 12_Bar-Rods

Applications of Titanium Bar & Rod

Titanium bars and rods are renowned for their exceptional properties, including strength, corrosion resistance, and lightweight characteristics. These qualities make them highly versatile, leading to a wide range of applications in various industries. Here's a glimpse of where titanium bars and rods are extensively used:

Ⅰ. Aerospace: Titanium's remarkable strength-to-weight ratio and resistance to high temperatures make it a preferred choice for aircraft components. It contributes to improved fuel efficiency and durability in the aerospace industry.

Ⅱ. Medical: Titanium's biocompatibility and corrosion resistance make it a crucial material in the medical field. It is commonly used for surgical implants, dental posts, and prosthetics, ensuring long-lasting performance and compatibility with the human body.

Ⅲ. Chemical Processing: Titanium's resistance to corrosion, especially in the presence of aggressive chemicals, makes it valuable in chemical processing. Titanium bars and rods are used in chemical vessels, heat exchangers, and tanks to maintain the integrity of equipment.

Ⅳ. Marine: In the marine industry, where exposure to saltwater is a constant challenge, titanium bars and rods are employed. They provide resilience against saltwater corrosion, making them suitable for various marine applications, including shipbuilding.

Ⅴ. Automotive: Titanium's lightweight yet strong properties contribute to enhanced fuel efficiency in the automotive sector. It is integrated into car components to reduce weight while maintaining structural integrity.

Ⅵ. Architecture: Titanium is used in architecture for both structural and aesthetic purposes. Its modern and sleek appearance, coupled with its strength, allows for innovative building designs that stand out.

The versatility of titanium bars and rods ensures their significance in various everyday products and specialized equipment across these industries and beyond. Their unique combination of properties makes them indispensable in applications where durability, corrosion resistance, and lightweight materials are essential.

Why choose SAFE Titanium?

If you're in search of the finest titanium fittings for optimal solutions to serve your clients, look no further than SAFE Titanium. Our meticulous practices ensure the delivery of top-tier titanium pipe fittings.

Ⅰ. Low MOQ

SAFE Titanium offers flexible production, accommodating orders from 1 to 10,000 units on demand.

Ⅱ. Expert Craftsmanship

With over a decade of experience in the titanium industry, our highly skilled and talented team ensures professional craftsmanship.

Ⅲ. Competitive Price

We guarantee the most competitive prices while maintaining the highest quality standards compared to other suppliers.

Ⅳ. Comprehensive Services

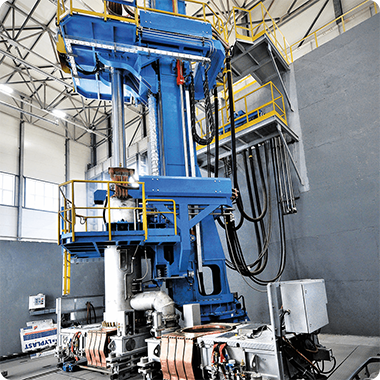

SAFE Titanium offers a wide array of processing equipment, meticulously maintained to ensure complete industry satisfaction.

Ⅴ. Fast delivery

Our mature production line facilitates 24/7 operations, enabling rapid turnaround and prompt delivery.

Ⅵ. Satisfaction Assurance

With a focus on quality and clear communication, we ensure that every step is streamlined for the ease and satisfaction of our clients.