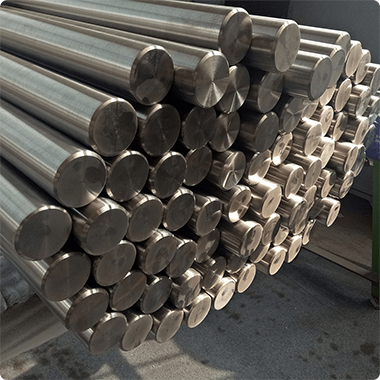

Titanium Round Bar

What is Titanium Bar?

A titanium bar is a solid piece of titanium metal that has been shaped into a cylindrical form. It is a highly durable and corrosion-resistant material that is widely used in aerospace, medical, and industrial applications. Titanium bars are commonly used as raw material for machined parts, fasteners, and prosthetic implants. They are also used in the construction of aircraft frames, engines, and landing gear due to their high strength-to-weight ratio and resistance to fatigue. Titanium bars can vary in size and grade depending on their intended use.

Advantages of Titanium Bar

Ⅰ. Strength and durability

Titanium is known for its high strength and durability. It has a high strength-to-weight ratio, which means that it can withstand a lot of force without becoming deformed or breaking.

Ⅱ. Corrosion resistance

Titanium bar is highly resistant to corrosion, making it ideal for use in environments where other metals would easily corrode. It can withstand exposure to saltwater, chemicals, and other corrosive substances, making it a popular choice in marine and chemical industries.

Ⅲ. Biocompatibility

Titanium bar is biocompatible, which means that it can be used in medical implants and devices without causing any adverse reactions or toxicity in the body. It is also commonly used in the production of orthopedic implants and dental implants.

Ⅳ. Heat resistance

Titanium bar has a high melting point and can withstand high temperatures without losing its strength or becoming deformed. This makes it ideal for use in high-temperature applications such as aerospace or industrial manufacturing.

Ⅴ. Lightweight

Despite its strength and durability, titanium bar is a lightweight material, making it ideal for use in applications where weight is a concern. It is commonly used in aerospace and automotive industries because of its lightweight properties.

1_Titanium-Sponge 2_Compacting-Electrodes 3_VAR-Melting

4_Finished-Ignots 5_Forging 6_Bar-Billets

7_Cutting-Billets 8_Extruding 9_Rolling

10_Straighting 11_Machining 12_Bar-Rods

Applications of Titanium Bar & Rod

Titanium bars and rods are renowned for their exceptional properties, including strength, corrosion resistance, and lightweight characteristics. These qualities make them highly versatile, leading to a wide range of applications in various industries. Here's a glimpse of where titanium bars and rods are extensively used:

Ⅰ. Aerospace: Titanium's remarkable strength-to-weight ratio and resistance to high temperatures make it a preferred choice for aircraft components. It contributes to improved fuel efficiency and durability in the aerospace industry.

Ⅱ. Medical: Titanium's biocompatibility and corrosion resistance make it a crucial material in the medical field. It is commonly used for surgical implants, dental posts, and prosthetics, ensuring long-lasting performance and compatibility with the human body.

Ⅲ. Chemical Processing: Titanium's resistance to corrosion, especially in the presence of aggressive chemicals, makes it valuable in chemical processing. Titanium bars and rods are used in chemical vessels, heat exchangers, and tanks to maintain the integrity of equipment.

Ⅳ. Marine: In the marine industry, where exposure to saltwater is a constant challenge, titanium bars and rods are employed. They provide resilience against saltwater corrosion, making them suitable for various marine applications, including shipbuilding.

Ⅴ. Automotive: Titanium's lightweight yet strong properties contribute to enhanced fuel efficiency in the automotive sector. It is integrated into car components to reduce weight while maintaining structural integrity.

Ⅵ. Architecture: Titanium is used in architecture for both structural and aesthetic purposes. Its modern and sleek appearance, coupled with its strength, allows for innovative building designs that stand out.

The versatility of titanium bars and rods ensures their significance in various everyday products and specialized equipment across these industries and beyond. Their unique combination of properties makes them indispensable in applications where durability, corrosion resistance, and lightweight materials are essential.

Your Trusted Source for Custom Titanium Rods & Bars

As a specialized titanium bar manufacturer and supplier, SAFETitanium is committed to providing you with high-performance titanium rods and bars, perfectly tailored to meet your specific needs. You can choose from our existing range of specifications or opt for a custom design. With a wide variety of grades and qualities to cater to diverse applications, SAFETitanium is your partner in elevating your projects with precision-engineered titanium solutions.

Tailored Titanium Bars and Rods to Suit Your Needs!

As seasoned experts in titanium bar and rod manufacturing, we take pride in our ability to accommodate customized orders. With over a decade of experience in the titanium industry, we excel in adjusting specifications, shapes, and various attributes to align perfectly with your project requirements.

Our Tailored Services Include

- Available Sizes: Ranging from 0.2″ up to 14″ in diameter.

- Available Grades: CP Grades 1, 2, 3, 4, 6AL-4V ELI, 6-4 Eli.

- Specifications on Offer: AMS-4928, 4930, 4965, 4967, MIL-T-9047, AMS-T-9047, ASTM-F-367, AMS-4975, 4978, AMS-4926, 4966.

- Surface Finishes: Options ranging from Black and pickling to Sand-blasting.

- Bar Shape: Includes Ti Round Bar, Ti Square Bar, Ti Hollow Bar, and Ti Hexagonal Bar.

- Applications: From Medical to Industrial and Aerospace niches.

Contact Us to Discuss Your Custom Titanium Bar and Rod Requirements!

Why Choose Titanium Bar & Rod from SAFETitanium?

SAFETitanium is a trusted manufacturing company equipped with state-of-the-art in-house facilities and a team of qualified engineers. Since 2009, we have been supplying titanium bars and rods to various industries, including engineering, electroplating, medical, precision parts, and more. Our commitment is to consistently deliver high-quality titanium products and establish ourselves as a reliable manufacturer in China.

- Unparalleled Expertise: We offer titanium solutions, not just products. With advanced technology and an experienced team, we excel in manufacturing, machining, and tailored bending processes.

- Professional Production: Our unwavering passion for craftsmanship is reflected in our work. We uphold the highest standards to ensure each titanium bar and rod meets our commitment to quality.

- Customer-Centric Commitment: Your satisfaction is our ultimate measure of success. Clear communication and meticulous attention to your requirements are our top priorities.

How to Buy Titanium Bar & Rod – A Complete Buyer's Guide

Titanium bars and rods find applications in a wide range of industries, from aerospace and medical to consumer products and more. Whether you're procuring titanium bars and rods for your specific projects or planning to sell them in your regional market, this comprehensive buyer's guide offers all the vital information you need to make informed decisions.

1. What is Titanium Bar & Rod?

Titanium Bar and Titanium Rod are both forms of titanium material, but they have some differences in characteristics and applications:

1. Shape and Size:

- Titanium Bar: Typically refers to titanium material with a rectangular or square cross-section. Their size and shape can be customized according to specific needs, and they are usually longer in length.

- Titanium Rod: Typically refers to titanium material with a circular cross-section. The diameter and length can be customized according to specific needs, and they are usually used in applications requiring cylindrical materials.

2. Production Process:

- Titanium Bar: Usually made through processes like extrusion, rolling, or forging, followed by cutting and machining to achieve the desired size.

- Titanium Rod: Usually made through extrusion or drawing processes, and further machined to achieve the required precision and surface quality.

3. Application Fields:

- Titanium Bar: Widely used in aerospace, marine engineering, chemical equipment, medical devices, and other fields, typically for structural components requiring high strength and corrosion resistance.

- Titanium Rod: Widely used for making screws, bolts, shafts, medical implants, sports equipment, and other applications requiring precision cylindrical materials.

4. Mechanical Properties:

Titanium Bar & Rod both have similar mechanical properties (such as strength, hardness, ductility, etc.) since they are made of the same material, but specific properties may slightly vary due to different manufacturing processes.

In summary, Titanium Bar and Titanium Rod mainly differ in shape and application fields. The choice of which form of titanium material to use depends primarily on specific application requirements.

2. Features of Titanium Bar & Rod

Titanium bars and rods are renowned for their exceptional qualities, making them a preferred choice in diverse industries:

- Strength-to-Weight Ratio: Titanium bars and rods offer a remarkable strength-to-weight ratio, making them ideal for applications where both strength and low weight are essential.

- Corrosion Resistance: Titanium is inherently resistant to corrosion, especially against saltwater, chlorides, and various industrial chemicals, ensuring durability in harsh environments.

- Biocompatibility: Due to its non-toxic nature, titanium is highly biocompatible, making it a top choice for medical implants and dental procedures, where safety and compatibility are paramount.

- High-Temperature Tolerance: Titanium maintains its strength in elevated temperatures, making it suitable for aerospace and industrial applications exposed to extreme heat.

- Versatility: Available in various grades, titanium bars and rods can be tailored to specific uses, from aerospace components requiring exceptional strength to intricate jewelry designs that demand both durability and aesthetic appeal.

- Ductility: Despite its strength, titanium is also ductile, allowing it to be drawn or stretched without breaking, facilitating intricate machining and fabrication processes.

- Low Thermal Expansion: Titanium exhibits a lower rate of thermal expansion compared to many other metals, ensuring stability under temperature fluctuations and contributing to its reliability.

These remarkable features collectively make titanium bars and rods the material of choice for a multitude of applications, from critical aerospace components to innovative medical implants and beyond.

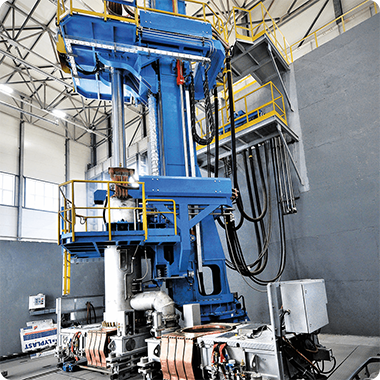

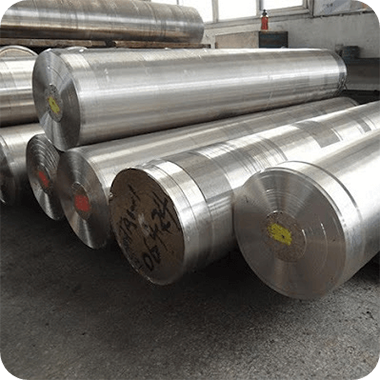

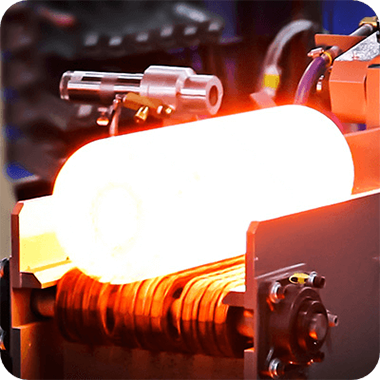

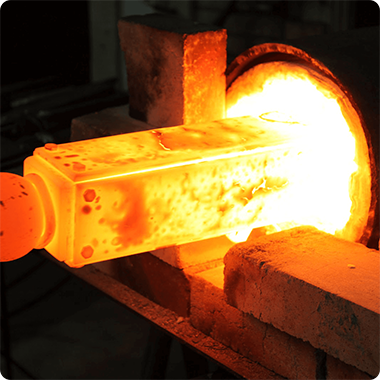

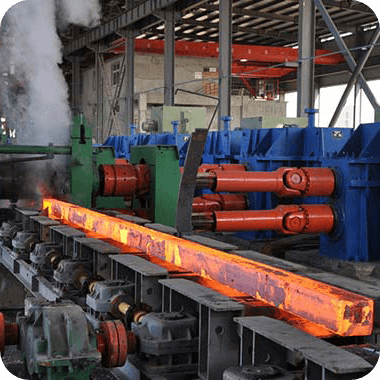

3. Production Process of Titanium Bar & Rod

This is an overview of the manufacturing process for titanium bars and rods, which are highly valued for their strength, lightweight properties, and corrosion resistance. These components find essential applications in aerospace, medical, architectural, and various industrial fields.

- Raw Material Selection: Start with carefully chosen high-grade titanium ore or sponge to ensure the raw material's purity and quality.

- Melting: Utilize a vacuum arc furnace to melt the raw titanium, resulting in a homogeneous ingot.

- Forging & Rolling: Heat the ingot and employ forging or rolling techniques to reduce its size and shape it into the desired bar or rod profile.

- Heat Treatment: Refine the microstructure and optimize the mechanical properties of the titanium through controlled heat treatment processes.

- Straightening & Finishing: Straighten the bar or rod and subject it to various finishing processes like turning, grinding, or polishing to achieve the specified surface finish.

- Quality Inspection: Thoroughly test each titanium bar and rod, including ultrasonic, visual, and dimensional checks, to ensure they meet the required standards.

- Packaging & Dispatch: Once approved, securely package the bars and rods for dispatch to be used in diverse applications across industries.

This comprehensive production process ensures that titanium bars and rods are manufactured to the highest standards, making them reliable and versatile components for various critical applications.

4. Overview of Our Titanium Bar & Rod Production Capabilities

This table provides a concise and organized view of our Titanium Bar and rod specifications.

| Feature | Specification |

| Standard | ASTM B348/ASME SB348, ASTMF67, ASTM F136, ISO-5832-2(3), AMS4928, MIL-T-9047G, JIS |

| Grade | Gr1, Gr2, Gr3, Gr4, Gr5 (Ti-6Al-4V), Gr7 (Ti-0.2Pd), Gr9 (Ti-3Al-2.5V), Gr12 (Ti-0.3Mo-0.8Ni), Gr23 (Ti-6Al-4V ELI) |

| Round Bar Size | Diameter: 2~300mm |

| Square Bar Size | 5.5mm~100mm; Thickness: 2~300mm |

| Flat Bar Size | Width: 10-300mm Thickness: 2-300mm |

| Hex Bar Size | 2~300mm |

| Length | 100~3000mm |

| Technical | Forged, Machined |

| Delivery State | Hot working state(R), Cold working state(Y), Annealing state(M) |

| Surface Finish | Acid surface, Polishing, Sand Blasting Finished, Bright, Polished |

| Shapes | Round, Flat, Square, Hexagonal, Rectangle |

| Rod Form | Round, Square, Hex(A/F), Rectangle, Billet |

| Applications | Metallurgy, electronics, medical, chemical, petroleum, pharmaceutical, aerospace |

5. Titanium Bar & Rod Grades: Understanding the Distinctions

Titanium bars and rods are categorized into various grades based on their chemical composition and intended applications. These grades determine specific characteristics of the titanium, such as strength, corrosion resistance, and biocompatibility.

This table provides a clear breakdown of some titanium bar and rod grades, their characteristics, and applications.

| Grade | Key Characteristics | Common Applications |

| Grade 1 | Optimum ductility, High corrosion resistance | Chemical processing, Marine |

| Grade 2 | Good strength, High corrosion resistance | Aerospace, Architecture |

| Grade 3 | High strength, Corrosion resistant | Industrial, Medical |

| Grade 4 | Highest purity, Superior corrosion resistance | Medical, Aerospace |

| Grade 5 (Ti-6Al-4V) | Exceptional strength, Heat resistance | Aerospace, Biomedical implants |

(Note: The table lists a few grades as examples. There are more titanium grades available tailored for specific uses.)

6. Different Forms of Titanium Bar & Rod

At SAFETitanium, we understand that various projects have distinct specifications and requirements. That's why we offer a range of forms to cater to your precise needs. Here's an overview of the different forms available for your specific applications:

- Round Bar: Round bars are perfect for machining and are widely used in industries such as aerospace and medical. Their cylindrical shape provides versatility for various applications.

- Square Bar: Square bars are chosen for their uniformity and ease of fabrication. They are ideal for constructing frames and structural components where consistency is crucial.

- Flat Bar: Flat bars offer a broader surface area and are commonly used in applications like blade manufacture or as structural components where a wider profile is required.

- Hexagonal Bar: Hexagonal bars are favored for their unique geometry, making them an excellent choice for fasteners and decorative elements. Their hexagonal shape provides added strength and a distinctive look.

With SAFETitanium, you're not just receiving a product; you're getting a tailored solution designed to meet your exact requirements.

Whether you need round, square, flat, or hexagonal bars and rods, we have the forms to suit your diverse needs.

7. Applications of Titanium Bar & Rod

Titanium bars and rods are renowned for their exceptional properties, including strength, corrosion resistance, and lightweight characteristics. These qualities make them highly versatile, leading to a wide range of applications in various industries. Here's a glimpse of where titanium bars and rods are extensively used:

- Aerospace: Titanium's remarkable strength-to-weight ratio and resistance to high temperatures make it a preferred choice for aircraft components. It contributes to improved fuel efficiency and durability in the aerospace industry.

- Medical: Titanium's biocompatibility and corrosion resistance make it a crucial material in the medical field. It is commonly used for surgical implants, dental posts, and prosthetics, ensuring long-lasting performance and compatibility with the human body.

- Chemical Processing: Titanium's resistance to corrosion, especially in the presence of aggressive chemicals, makes it valuable in chemical processing. Titanium bars and rods are used in chemical vessels, heat exchangers, and tanks to maintain the integrity of equipment.

- Marine: In the marine industry, where exposure to saltwater is a constant challenge, titanium bars and rods are employed. They provide resilience against saltwater corrosion, making them suitable for various marine applications, including shipbuilding.

- Automotive: Titanium's lightweight yet strong properties contribute to enhanced fuel efficiency in the automotive sector. It is integrated into car components to reduce weight while maintaining structural integrity.

- Architecture: Titanium is used in architecture for both structural and aesthetic purposes. Its modern and sleek appearance, coupled with its strength, allows for innovative building designs that stand out.

The versatility of titanium bars and rods ensures their significance in various everyday products and specialized equipment across these industries and beyond. Their unique combination of properties makes them indispensable in applications where durability, corrosion resistance, and lightweight materials are essential.

8. Surface Finish Options for Titanium Bar & Rod

The surface finish of a titanium bar or rod can significantly influence its aesthetic appeal, performance, and suitability for certain applications. At SAFETitanium, we offer a range of finish options tailored to meet diverse needs:

- Polished: Provides a mirror-like, high-gloss finish that's ideal for decorative and aesthetic purposes.

- Sand Blasted: Results in a uniformly rough texture, enhancing grip and offering a matte look.

- Acid Washed: Delivers a smooth, clean surface by removing impurities and minor imperfections. Often preferred for medical and aerospace applications.

- Black (Oxide): Retains a natural, oxide-rich surface, which provides a measure of corrosion resistance.

- Pickling: Removes oxide layers and minor surface imperfections, yielding a matte, smooth finish suitable for many industrial applications.

By understanding and selecting the appropriate surface finish, customers can ensure that their titanium bar or rod is best suited for its intended use, whether it be for aesthetics, function, or both.

9. Considerations When Purchasing Titanium Bars or Rods

When you're in the market for titanium bars or rods, making an informed decision is crucial. To ensure you select the right material for your specific needs, consider the following critical factors:

- Grade & Alloy: Titanium comes in various grades and alloys, each with distinct properties. Choose the grade that aligns with your application requirements. Factors to consider include strength, corrosion resistance, and formability.

- Dimensions: Verify the diameter, length, and other specific measurements of the titanium bar or rod to ensure they match your project specifications accurately. Precision in dimensions is essential for a successful application.

- Surface Finish: The surface finish of the titanium can impact both performance and aesthetics. Different finishes are available, ranging from polished to sandblasted. Select the finish that suits your application's functional and visual requirements.

- Certifications: For critical applications like aerospace or medical implants, it's essential to ensure that the titanium product meets specific standards and certifications. These certifications guarantee the quality and reliability of the material.

- Supplier Reputation: Choose a reputable supplier with a track record of providing quality products. A trustworthy supplier can also offer valuable guidance to help you select the best titanium material for your needs.

- Price: While cost is a factor, it's important not to compromise on quality. Investing in a higher-grade titanium product may result in long-term benefits, including fewer maintenance issues and enhanced performance.

- Application Specifics: Consider the environment in which the titanium bar or rod will function. Factors such as temperature, pressure, exposure to corrosive materials, and other environmental variables can influence your choice of titanium grade and alloy.

By carefully weighing these considerations, you'll be well-equipped to make a purchase that effectively and efficiently serves your specific needs, whether for aerospace, medical, industrial, or other applications.

10. How to Select a Reliable Titanium Rod & Bar Supplier?

Selecting the right supplier for titanium rods and bars is a critical decision that can significantly impact the success of your project. To make an informed choice, consider the following key factors:

Experience: Opt for suppliers with a proven track record and extensive experience in the titanium industry. A supplier with a long history of successful operations is more likely to provide quality products and services.

Certifications: Look for suppliers that adhere to recognized quality standards, such as ISO or ASTM certifications. These certifications ensure that the products meet established industry benchmarks for quality and performance.

Product Variety: Choose suppliers that offer a wide range of titanium grades, finishes, and sizes. This diversity allows you to select the specific products that best match your project requirements.

Transparent Pricing: Ensure that the supplier provides clear and transparent pricing with no hidden charges. A straightforward pricing structure helps you budget effectively and avoid unexpected costs.

Customer Feedback: Check customer reviews and testimonials to gain insights into the quality of both the products and the supplier's services. Positive feedback from previous customers is a good indicator of a supplier's reliability.

Supply Chain: Consider whether the supplier has a strong and reliable relationship with raw material providers. A robust supply chain can contribute to product quality and value.

Customer Service: Evaluate the responsiveness and professionalism of the supplier's customer service team. Quick and well-informed responses to your inquiries demonstrate a commitment to customer satisfaction.

Delivery Times: On-time deliveries are crucial for maintaining project timelines. Inquire about the supplier's delivery capabilities and track record to ensure they can meet your project's schedule.

Customization: Confirm whether the supplier can tailor titanium rods and bars to your specific specifications. Customization options are essential for projects with unique requirements.

After-Sales Support: Assess the supplier's post-purchase policies, including warranties and return procedures. A supplier that offers reliable after-sales support demonstrates confidence in the quality of their products.

By carefully considering these factors, you can confidently select a titanium rod and bar supplier that aligns with your project's needs, ensuring a successful and efficient procurement process.

11. Summary

Titanium bars and rods, celebrated for their exceptional strength and resistance to corrosion, play a vital role in industries like aerospace, medical, and architecture. However, selecting the right titanium products can be a daunting task for new buyers.

SAFETitanium, a renowned manufacturer, stands out as a trusted source for top-quality titanium bars and rods. Our comprehensive services guarantee precision at every step, from selection to delivery, making SAFETitanium the preferred choice for high-grade titanium needs.

Moreover, we offer the flexibility to produce customized samples tailored to your exact specifications in most cases. This ensures that you receive the precise titanium bars and rods you require for your specific projects.