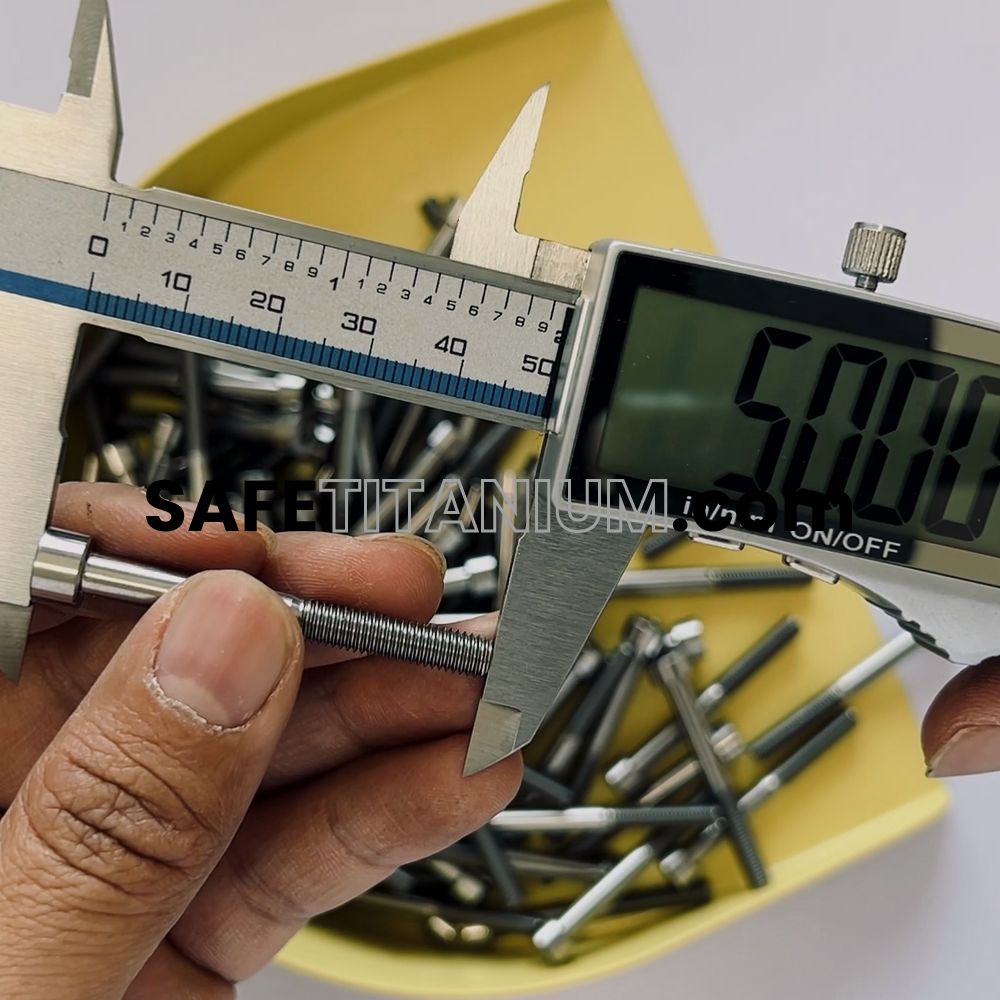

GR2 DIN912 M12×110mm Ti Screws

What is Titanium Screws?

Titanium screws are a type of fastener made from the metal titanium.

They are extensively used in various industries, including aerospace, medical, automotive, and construction.

Compared to traditional screws made of steel or other metals, titanium screws are much stronger, lighter, and more resistant to corrosion, this makes them ideal for applications where weight reduction, durability, and strength are critical factors.

They are also biocompatible, making them a popular choice in medical implants and surgical instruments.

Due to their exceptional properties, titanium screws are often more expensive than their counterparts made from other materials.

However, the benefits that they offer in terms of quality, strength, and durability make them worth the investment.

Why choose Titanium Screws?

01/High strength

Titanium screws have high tensile strength, which makes them resistant to shearing and deformation. This strength also translates to better holding power and stability.

02/Lightweight

Titanium screws are lightweight in comparison to other materials, such as steel and copper. This makes them ideal for applications where weight is a critical factor, such as aerospace and medical implants.

03/Corrosion resistance

Titanium has excellent resistance to corrosion and oxidization, even in harsh environments. This makes it ideal for use in marine and other corrosive environments.

04/Biocompatibility

Titanium screws are biocompatible, which means they are safe to use in medical implants and prosthetics. This property also makes them ideal for applications in the food and beverage industry.

05/Non-magnetic

Titanium screws are non-magnetic, which makes them ideal for use in applications where magnetic interference is a factor, such as in MRI machines.

06/High temperature resistance

Titanium screws can withstand high temperatures without losing their strength and structural integrity. This makes them ideal for use in high-temperature environments, such as in jet engines.